What’s new in the pipe laying industry?

Aktie

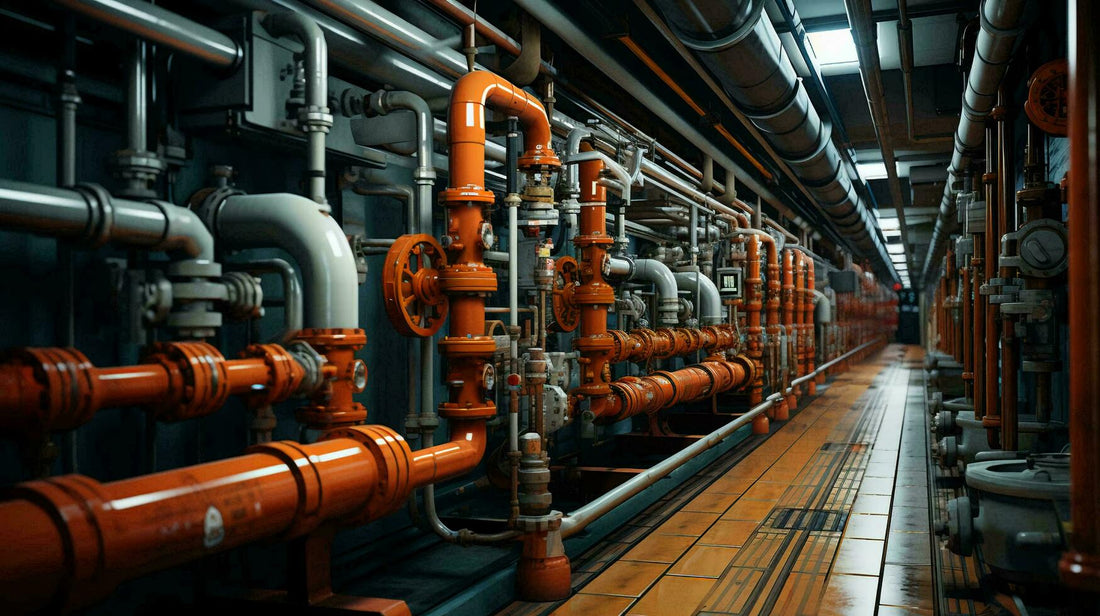

The pipe laying industry is undergoing significant transformations driven by advancements in technology, sustainability, and safety. Companies are increasingly adopting eco-friendly materials, such as recycled polyethylene and polypropylene pipes, while trenchless technology minimises environmental disruption. Automation plays a crucial role, with robotics and drones enhancing efficiency and safety during installations. Enhanced monitoring systems using smart sensors are now commonplace, allowing for real-time detection of leaks and corrosion, which helps extend the lifespan of pipelines.

The integration of GPS and GIS technology improves project planning by providing precise mapping, reducing errors, and preventing damage to underground utilities. New joining techniques, like electrofusion and thermal butt fusion, offer reliable, leak-free seals, while digital twin technology enables real-time monitoring and optimisation of pipeline systems. Furthermore, 3D printing is revolutionising the production of custom pipe fittings and tools, streamlining operations and reducing supply chain delays.

As the industry faces a growing demand for skilled labor, companies are investing in enhanced training programs, including virtual reality simulations for practical experience. Overall, these innovations are positioning the pipe laying industry for a more efficient, sustainable, and safer future.